What is a Sorbent Trap Mercury Measurement System?

What is a Sorbent Trap?

A sorbent trap is a tube, typically made of borosilicate glass, with sections of sorbent that is specially formulated to capture mercury separated by an inert material such as glass wool.

There are many different types of traps, but we’ll start by talking about the mercury (Hg) trap that is traditionally used for continuous mercury monitoring using Performance Specification 12B. This specification has been written into regulation as an allowable measurement technology for mercury monitoring in the Mercury Air Toxics Standard (MATS) for utility boilers, the Portland Cement MACT, Commercial/Industrial Incinerator (CISWI) MACT, the Boiler MACT, and the Sewage Sludge Incinerator (SSI) MACT. Later we will cover some other traps useful for mercury control technology optimization testing.

PS 12B mercury sorbent traps have three sections of halogenated carbon (usually iodine). The traps are used to capture vapor-phase Hg in various sampling environments, but their most common application is long term sampling, which typically lasts 7-14 days.

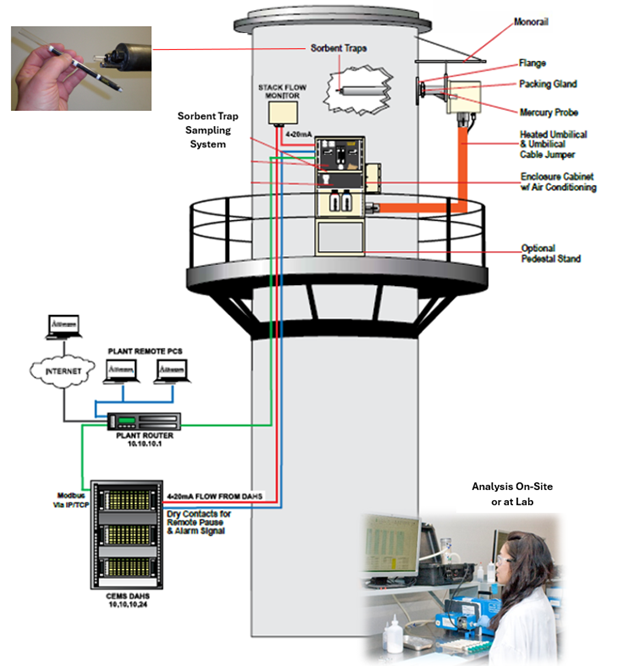

Sorbent traps are sampled in-situ, meaning the Hg is captured directly in the flue gas, thereby avoiding problems with sample gas transport. For long term sampling, the traps are sampled with permanently installation sampling systems (like the one pictured above).

What is a sorbent trap sampling system?

Typically, a sorbent trap sampling system is composed of:

- The heated probe that holds the sorbent traps.

- A moisture removal device. Typically this is a sample conditioner for long-term sampling.

- The sampling console which contains the sample pumps, mass flow controllers or dry gas meters, probe temperature controllers, and vacuum gauges.

There are multiple vendors for the permanently installed PS 12B sampling systems that we could recommend. Feel free to reach out to Alexandra and she will be happy to discuss the options currently on the market.

There are also portable sampling systems. The advantage of having a portable Hg sorbent trap sampling system is that it allows you to sample anywhere in the power plant, with minimal time required to move the equipment and begin sampling. These systems are not traditionally used for PS 12B but rather were designed for Reference Method 30B as well as engineering studies, mercury speciation testing, and short-term spot checks. You can also sample a variety of other analytes, including HCl, NH3, SO3, selenium, arsenic, and other metals with these systems. You can learn more about portable sorbent trap sampling systems here.

How Does the Method Work?

Two sorbent traps are inserted into a probe.

Two sorbent traps must always be used according to the method as part of the quality assurance requirements.

The sample flows into the glass tube and the mercury is captured by the first sorbent section called the analytical bed.

The flue gas comes in contact with this first section immediately as sampling commences, there is nothing in front of the traps so there is no potential for scrubbing or bias.

The second section is a quality assurance requirement and is used to ensure that all the mercury is in fact being captured inside of the primary section of the sorbent trap. Only a very small proportion is allowed to have broken through into the second section in order for the sample to be valid.

The third section is typically spiked with a known amount of Hg based on the expected concentration of the source. This is used for quality control of the entire sampling and analysis process to validate that nothing has gone wrong throughout the sampling and analysis program.

After the sorbent traps are secured inside of the probe, the probe is inserted into the sampling port and the pumps are turned on.

The sampling duration can be anywhere from 10 minutes up to 14 days depending on the application. PS 12B sorbent traps are typically sampled for an average of 7 days.

After the sampling is complete, the volume of sample that passed through the sorbent traps is recorded and the sorbent traps are removed. They are then brought down to an on-site lab or sent off-site for analysis.

How analysis is done

Sorbent traps are typically analyzed via atomic absorption spectrometry.

Each sorbent section is individually emptied out into a quartz ladle and placed into the analyzer for analysis.

Analysis time is about 5 minutes per trap and the analyzer determines the mass of mercury in nanograms (ng) present on each section.

Mass of mercury divided by the sample volume will give you the average mercury concentration in the flue gas during the entire duration of that sampling period in micrograms per dry standard cubic meter (ug/dscm).

The Sorbent Trap Method is a simple method that makes time-integrated Hg measurements with sampling duration up to 14 days.

There are many advantages to using this method for continuous mercury monitoring. You can read more on these advantages here.

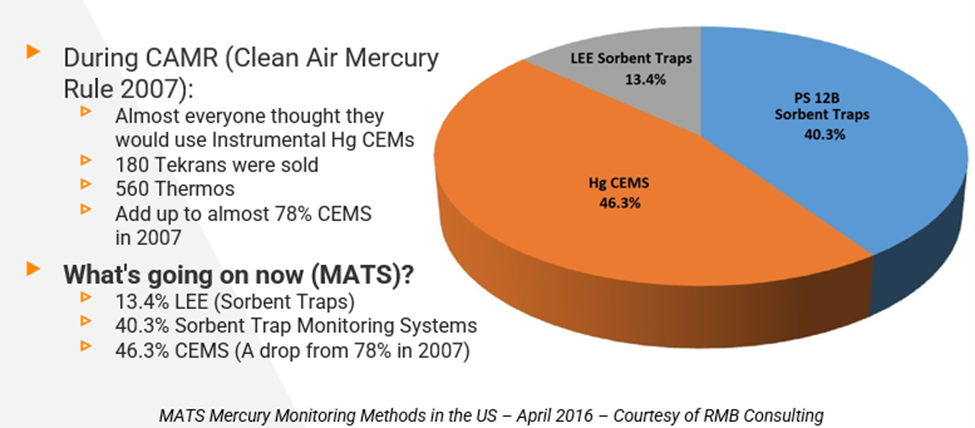

In the United States, there has been a push for using Sorbent Trap Systems. In 2007 78% of Utilities purchased Instrumental CEMs for compliance monitoring. Since then, this number has decreased.

Based on data from 2016, only 46.3% of plants were using Instrumental CEMs.

It is now 2024, and the percentage of instrumental CEM users is even lower. More plants have shut down and many have turned to the sorbent trap method because it is a simpler and more cost-effective option. The percentages are closer to 35% still using instrumental CEMs and the remainder are a combination of PS 12B Sorbent Trap Monitoring Systems and LEE testing using sorbent traps.

Many users have turned to traps because of cost savings. Others have turned to traps because of ease of use and certainty of passing the annual RATAs, while others prefer to report with an average.

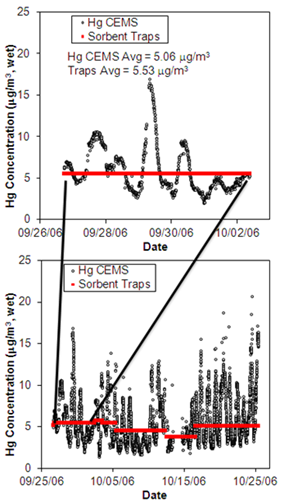

There is not much difference in terms of reporting with sorbent traps or instrumental CEMs. Most rules are written for rolling average reporting. Sorbent traps allow users to report with an average over the sampling period while CEMs give peaks and valleys which must then be averaged by the plant DAHS.

Sorbent traps are incredibly versatile and with the use of portable sorbent trap sampling systems, traps can be used throughout the plant for all kinds of engineering and mercury control optimization testing.

You can read more on mercury control optimization testing using traps here.