All the advantages of using sorbent traps for compliance monitoring AND mercury concentration data in REAL-TIME!

In our previous blog post we discussed the advantages of using mercury sorbent traps for Hg compliance monitoring. If you missed that article, you can find it here.

Though we are wholehearted believers in sorbent traps for mercury monitoring, we recognize that there is one major downside to using sorbent traps alone. The data is not in real-time.

This is where a mercury process monitor shines.

A real-time CEM that you do not certify and cannot certify.

But you can trust the data and utilize it to make immediate process changes as well as optimize your Hg control technology thus saving you money on it.

This is why we designed the 915J Mercury Process Monitor.

You are probably thinking to yourself, “but Alexandra just went over all of the challenges with Hg CEMs in this other article.”

Well, there are some things that make the Ohio Lumex 915J Mercury Monitor very different from others on the market.

I won’t be able to get into all the details, but I want to mention some of the main points.

The system was actually developed for our internal field services group, and we used it for hundreds of projects in the lead up to MATS and the Portland Cement MACT to do performance evaluations and engineering studies as they related to various mercury control technologies.

In this period, we got a lot of actual hands-on field experience operating these systems which helped us fine-tune the final design that we currently sell as a permanently installed system

Remember those measurement challenges we previously discussed in this series:

- Low Concentrations

- Interferences

- Sample Transport

- Testing Location

- Equipment Limitations

You can find the detailed article here.

This system was strategically engineered to deal with each one of those.

To handle low levels, our measurement technology is atomic absorption spectroscopy with a multi-pass cell and Zeeman correction.

Actually, this spectrometer is the same one used in the M324 system (the sorbent trap analyzers that 99% of the market uses). It was originally designed for ambient air monitoring for Hg spill response and clean up verification. Incredibly low levels. We still demo the instrument at ambient air conferences by having customers exhale near it and measure how much mercury is volatilizing from the silver fillings in their teeth. Down to 2 ng/m3 in ambient air.

This is a very important point because the greater your sensitivity the more accurately you measure even at low levels. This really distinguishes us because in an industrial application, the resolution is 0.1 micrograms per cubic meter.

With this sensitivity, the 915J, for example, can accurately tell that a PAC injection rate gets a unit down to 1ug/dscm as opposed to another injection rate which gets down to 0.9ug/dscm. This gives you the ability to optimize Hg control strategies and leads to significant cost savings.

To deal with Interferences we utilize dilution probes like other CEM manufacturers. These decrease the moisture level and acid gases that would otherwise damage internal components of the monitors and/or interfere with the measurements. But, we also utilize Zeeman background correction. An incredibly innovative technology which was noticed by EPA when we first started Ohio Lumex and is still used to this day by every region of the EPA for mercury spill response.

Then there is Sample Transport, which is quite an issue for other CEMs. Most other instruments need to be placed into temperature controlled CEMs buildings constructed at the bottom of the stack and long heated sample lines bring the sample from the port to the instrument where it is analyzed.

On the other hand, the 915J console sits inside of a NEMA 4X enclosure which is self-heated and cooled. This allows for installation as close as possible to the sampling port. The system can even stand outdoors on a roof or platform. Many of our installations are like this. This allows us to have short sample lines. We also handle all of our sample conditioning right at the port in the probe head, so we only send treated clean sample through the short sample lines. This means that we do not need to keep those lines at high temperatures like other systems. High-temperature lines are a common point of failure and can be very expensive to replace.

Then there is the Testing Location.

Remember the origin of these monitors. Temporary modular installations pre and post Hg control technologies. It’s still a modular system that allows the opportunity for a client to test at upstream locations temporarily if Hg measurements are ever needed upstream of an Hg control technology or a different plant location. The console and probe can be moved or a rental unit can be used. We have plenty of these monitors in our rental fleet.

This modularity also lends itself to one of the biggest advantages of our Hg CEM. It allows for fast maintenance and even shipping of the console to us if ever needed while we overnight another console. Back up and running very quickly. As opposed to other monitors where you must call in the manufacturer and then wait and wait and wait for parts and service.

The 915J is a different breed of Mercury CEM. It was not built to abide by a Performance Specification and so the limitations to the 915J are far fewer by comparison.

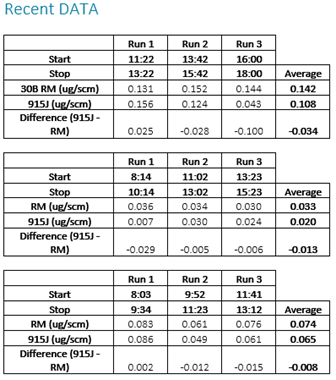

Installation time is about 2 hours. We let the system equilibrate overnight and then run traps against it (like a mini-RATA) to verify it before installation is complete.

The system has a built-in elemental Hg calibrator. No other calibration source is needed. The calibrator is extremely stable and only needs to be serviced once every 2 years. Also, there are no liquids required for operation. It is a completely dry system.

Typical maintenance on the 915J is 4-6 hours on a quarterly basis. There are easy to swap out filters and no expensive consumables. Oh, and the monitor itself is less expensive than having to replace one 600ft umbilical. Sorbent trap sampling systems are also cost effective and average about 2 hours per week on trap changeouts and maintenance of the systems. Click here to read more about sorbent trap advantages for Hg Monitoring.

This hybrid approach is easier, more cost effective, and more reliable than purchasing and maintaining a PS 12A Compliant Hg CEM.

Don’t believe us, talk to our customers! You can find a few of them here, or, let us prove it to you. Contact Alexandra for a more detailed presentation and proposal.