Our first article in this series went into detail on why measuring mercury in emissions is especially difficult… and how awesome you are because you are doing it!

If you missed it, you can find it here.

To recap the main measurement challenges:

- Low Concentrations

- Interferences

- Testing Location

- Sample Transport

- Equipment Limitations

We also discussed these challenges as they relate to the instrumental CEMs previously purchased for MATS and NESHAP. If you missed that article, you can find it here.

It is due to these challenges that so many customers have switched to sorbent traps via Performance Specification 12B for mercury compliance monitoring.

If you are unfamiliar with mercury monitoring using sorbent traps you can read about it here.

Sorbent traps present clear advantages over other methods and instruments.

1. Low Concentrations

First is the ability of sorbent traps to accurately measure very low levels. In theory there is no detection limit for sorbent traps because the volume of sample that passes through the tube can be increased as needed to collect a large enough mass of analyte on the sorbent. It is as simple as increasing the run duration or flow rate.

2. Interferences

Next is the ability to eliminate interferences by combining sorbent media that is selective to the desired analyte with the optimal analytical technique. This has been proven with hundreds of thousands of runs. The sorbent trap method EPA Method 30B is even the reference method for mercury monitoring. This is the gold standard for evaluating all Hg CEMs used for compliance reporting and must be conducted annually for each of them in the USA.

3. Testing Location

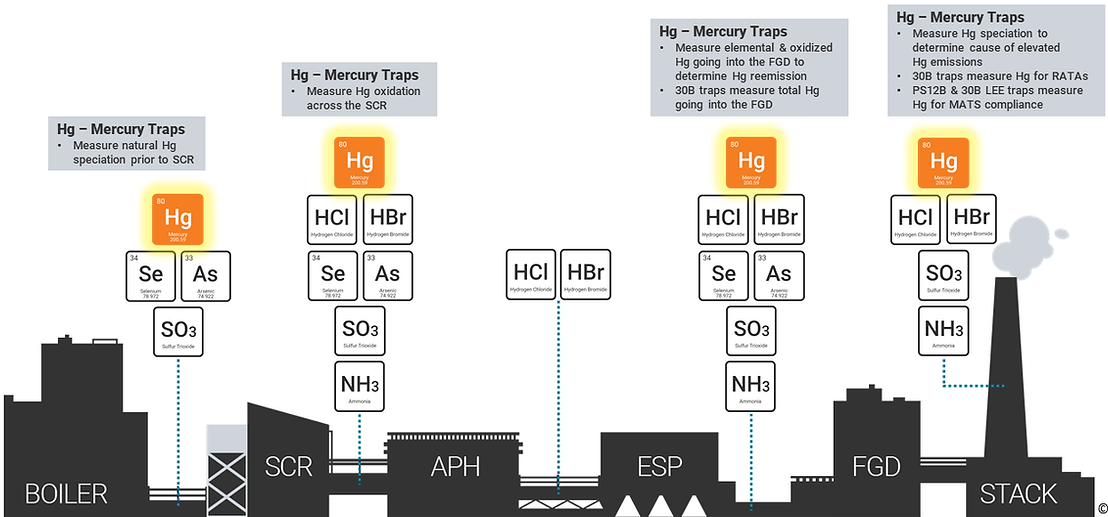

Manufacturers also have the flexibility to either modify the sorbent trap itself or the sampling technique based on the specific conditions encountered in the field or at the testing location. Low pressure drop glass or prefilters can be used so that a client can sample for 7 days without encountering high vacuums. Moisture resistant glass allows for sampling in saturated environments. Acid gas scrubbers capture interferences before they hinder the performance of the sorbent trap. The ability to modify the sorbent traps for the specific conditions encountered allows for sampling throughout the plant in any location where mercury measurements are needed. Sorbent trap equipment is also light, durable, and extremely portable which makes it easy to use throughout the plant.

The sorbent trap method is trusted by US EPA and is included in the US EPA Mercury Monitoring Toolkit. What’s “The Toolkit?” It’s a combination of all equipment recommended by US EPA at international meetings and conferences for monitoring mercury from coal combustion sources.

4. Sample Transport

And finally, the most significant advantage is that sorbent traps are measured in-situ, thus eliminating all the problems associated with extracting and transporting a sample. Instead of having to pass through sometimes hundreds of feet of lines and other components before finally being measured, sorbent traps capture the analyte right in the stack or duct before it has an opportunity to change characteristics or otherwise be affected.

Sorbent trap methods are straightforward, the equipment is inexpensive, and maintenance on it is low.

5. Equipment Limitations

With permanent installations, sorbent trap users report an average of two hours per week on sorbent trap changeouts, system audits, and maintenance. Sorbent trap systems are simple. So simple that a CEMs technician can operate and maintain a system on their first day. Plus, the data availability speaks for itself. On average it is greater than 97%.

PLUS: A MAJOR ADVANTAGE!

(*Bethany White from RTP Environmental emailed this succinct explanation to me recently…I refer to her as “Brilliant Bethany”…just FYI.)

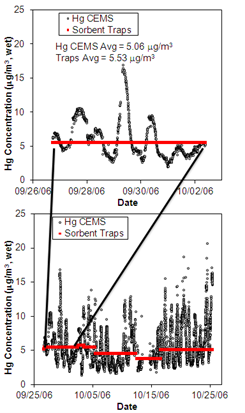

There is one other exceptionally unique advantage of sorbent traps. The sorbent trap method allows plants to report their concentration data with averages rather than publicly divulge the peaks and valleys of Hg emissions data which can be dramatic depending on the source and process conditions.

Let’s explore this data reporting in a little more detail *. Concentration data (ug/scm) as well as hourly emission rate data (lb/TBtu or lb/GWh) are reported as hourly averages to EPA. Hourly peaks and valleys in concentrations are visible for instrumental Hg CEMS and are directly reported to EPA. This data is easily accessible to the public, even without a Freedom of Information Act (FOIA) request. With sorbent traps, since the concentration is averaged over the entire sampling period, they report the SAME hourly concentration value for EACH hour in the sampling period (i.e. 7 days). Some variation in emission rate is visible for both types of systems based on changes in CO2 (in the case of lb/TBtu) or flow and load (in the case of lb/GWh), but they are more muted for sorbent trap systems since they are not also dealing with changes in concentration at the same time as the changes in other parameters.

There is no difference when it comes to compliance reporting using sorbent trap systems or instrumental CEMs. Both provide emissions data over the averaging period required by the regulations. This is because most rules are written with rolling averages for compliance. In other words, compliance is based on either a 30, or even 90, boiler operating day average which can be made up of hourly peaks and valleys (in the case of instrumental Hg CEMS) or sampling period averages (in the case of sorbent traps). The number that is used for compliance reporting is averaged for both system types.

EPA can also ask for sub-hourly data but that is somewhat unusual. In the case of sorbent traps there would not be sub-hourly data to submit, in the case of instrumental Hg CEMS, there would.

BUT … AND THERE IS A BUT!

We recognize that the biggest disadvantage of sorbent traps is that they are not a real-time measurement method and depending on the lab, it could take a few days to a few weeks to get results back.

Sometimes that is too late to fix an immediate problem.

Often, you need to know the Hg levels in real-time in order to alert you to a problem so you can make process changes or improve Hg control.

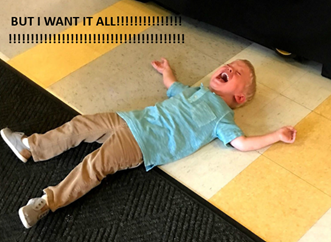

OH MY!

Well, I can see you are upset…

Would another option make you feel better?

Don’t tell my toddler, but… you CAN have it all!!!!